Products: DYDTEC

DYDTEC Combustion

DYDTEC Combustion is a provider of intelligent professional solutions in the field of industrial combustion in China

With about 11,000 square meters of production and R&D bases in Shanghai and Suzhou, it has strong non-standard customization and R&D capabilities for combustion systems, which can meet customer needs for all applications and working conditions; in low nitrogen, low carbon, hydrogen fuel and digitization. There is a wealth of practical application accumulation in the field of safe and energy-saving combustion control technology.

View DYDTEC Products

Burners

TECFG Burner

TECFG Gas Burner is a high-precision temperature control burner designed by DYDTEC for medium and high temperature industrial applications. Tecflame is a nozzle mixing burner with the characteristics of high flame velocity, ultra wide power regulation range, sufficient and stable combustion and high heat transfer efficiency. It is widely used, such as ceramic shuttle kiln, glass tempering furnace, tempering furnace, quenching furnace, annealing furnace, RTO, thermal oxidation furnace, drying furnace, preheating furnace, etc.

Parameter

- Capacity range: 105kw-5300kw

- Regulation ratio 50:1

- Applicable maximum combustion chamber temperature 1540 ℃

- Maximum flame velocity 150m/s

- Preheating combustion air can be used

- Low CO and NOx emissions

- Direct ignition with spark plug

- Applicable to natural gas and LPG

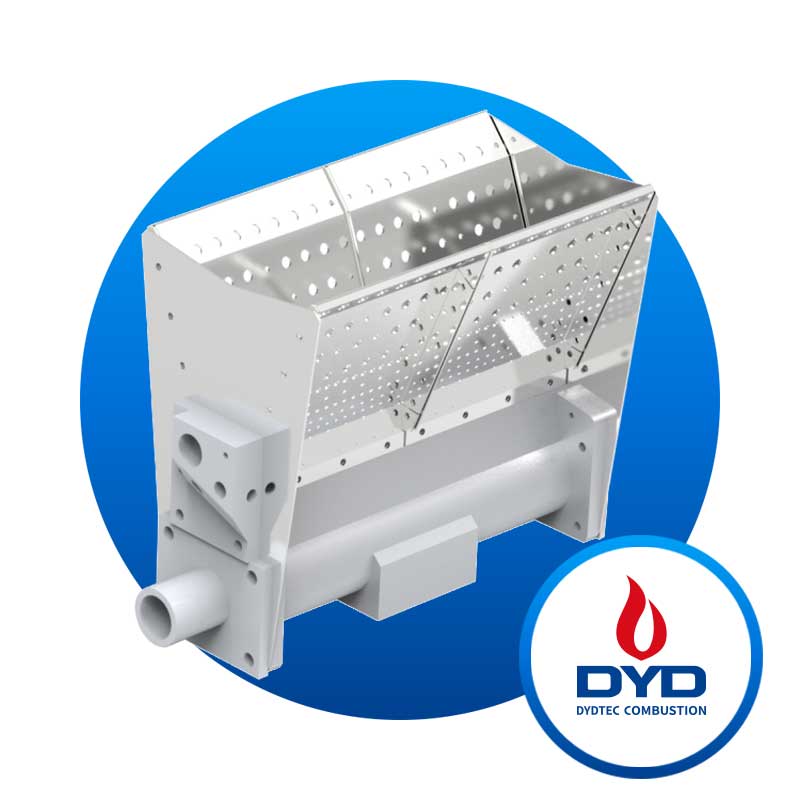

Linofire Burners

Linofire serie burners are designed to heat fresh air, medium & low-temperature air (direct-fired). They are used for processes such as heating, drying or curing for the environment or objects in automotive, medical, food and chemical industries. The burners may also be installed at downsteam or preheating section to ensure higher heating temperature.

Parameter

- Designed for direct-fired air heating and medium/low temperature drying

- Modular design (rated power: 240kW/ft)

- Short flame length (max. length: 700mm)

- ANSI/CSA standards

- Turndown 30:1

Linofire-WB Burners

Linofire-WB serie burner is the direct-fired air heating burner designed based on the safety standard EN746-2 of the EU gas industry. The Linofire-WB burner can be installed on the side wall of the furnace to produce a wide range of flame heating area in a short period of time and can be used in a variety of low and medium temperature heating application scenarios such as oven, industrial drying furnace and air heater, especially suitable for working conditions with limited heating space.

Parameter

- 6 types of specifications optional; all-metal structure

- Capacity: 145kW~870kW

- Stable and clean combustion; low NOx level

- High turndown to 40:1, faster and accurate temperature regulation

- Suitable for natural gas and LPG

- Low gas pressure required

- Integrated design, easy to install, easy to operate,easy to maintain

PTC Burners

PTC-F gas burner is a high-precision temperature control burner designed by DYDTEC for industrial applications. It has the characteristics of wide capacity regulation range, sufficient combustion, reliability and stability, high convective heat transfer efficiency and so on. It has a wide range of applications, such as hot air heater, drying furnace, preheating furnace, ceramic shuttle kiln, glass tempering furnace, quenching furnace, annealing furnace, RTO, thermal oxidation furnace, etc.

Parameter

- Applicable maximum combustion chamber temperature 950 ℃

- High convective heat transfer efficiency

- Turn down ratio 20:1

- Flexible adjustment to meet a variety of temperature control needs

- Excellent low fire performance

- Perfect for both high and low temperature applications

- Low CO and NOx emissions

- Applicable to natural gas and LPG

- Direct ignition with spark plug

Combustion Systems

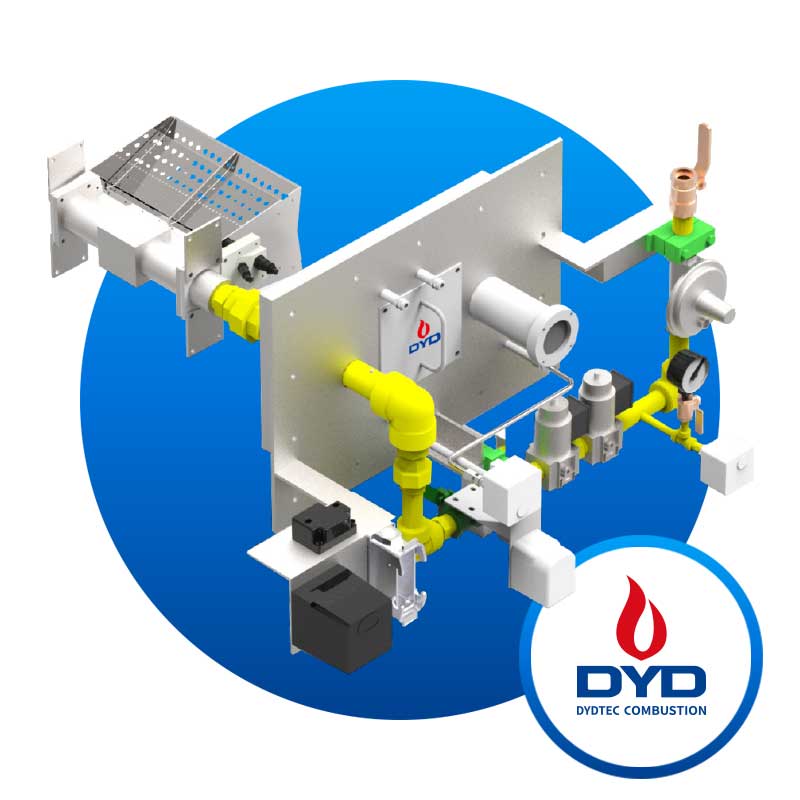

PLPP Integrated System

Parameter

- Heating value: 145~870kw.

- Turndown ratio: 10:1.

- Maximum temperature rise: ≤530℃

- Air velocity: 8-20 m/s.

- Hearth back pressure range: -400Pa~+100Pa.

- Gas inlet pressure: 20-30kpa.

- Stable and clean combustion.

- Low emission of nitrogen oxide.

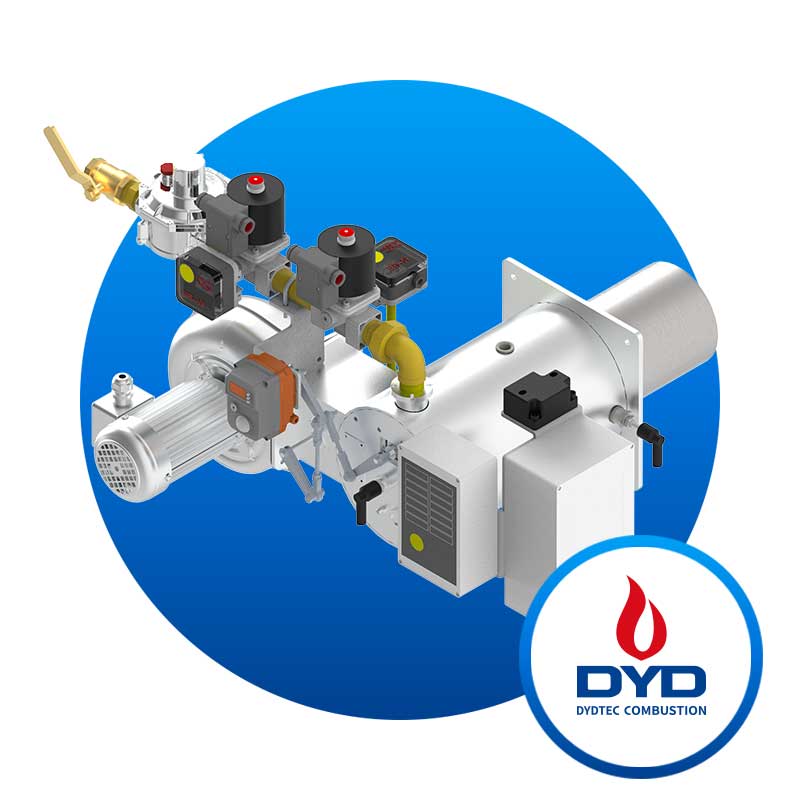

NECO Integrated System

NECO is a combustion system designed by DYDTEC according to standard EN746-2. It provides an integrated combustion solution, including burner, pressure regulating valve, filter, pressure gauge and other equipment. The automatic gas control valve controls the thermal power of all working ranges. The gas is mixed with air along the mixing cone in the burner through the nozzle to produce a short and stable flame.

Parameter

- Two specifications are available, all metal components

- Capacity: 4kW~300kW

- Stable and clean combustion, low NOx emission

- High precision adjustment ratio up to 40:1

- Faster and more accurate temperature adjustment

- The required gas pressure is low

- Integrated design, simple installation

- Easy to operate and maintain

- Fans and motors with multistage voltage and frequency

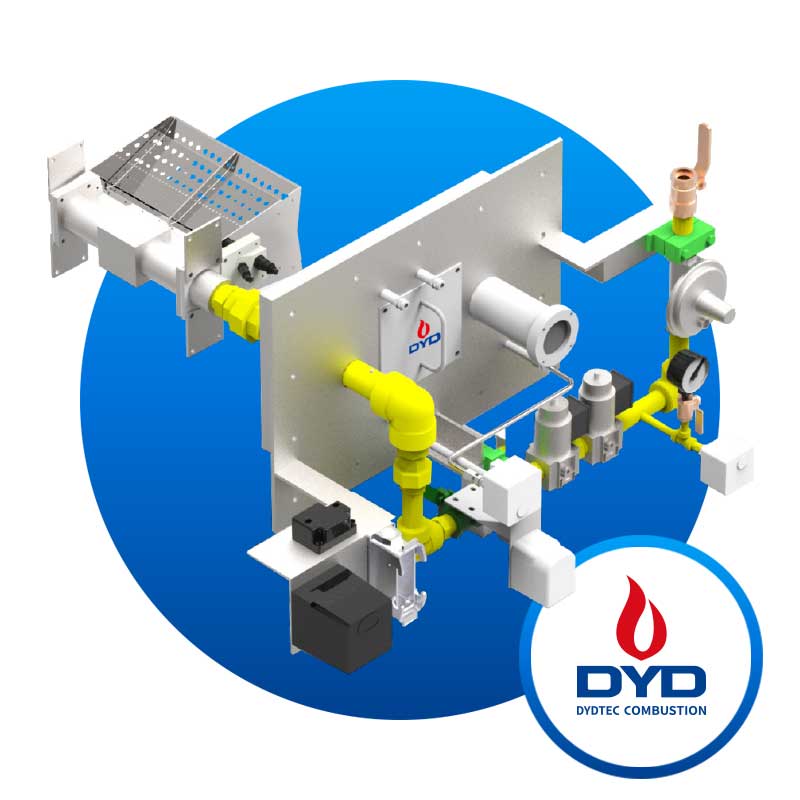

PIL Integrated System

Parameter

- Heating value: 200kw/ft.

- Turndown ratio: 10:1.

- Upstream temperature: ≤230℃

- Downstream temperature: ≤450℃

- Flame length: ≤

- Hearth back pressure range: -400Pa~+2000Pa.

- Gas inlet pressure: 20-30kpa.

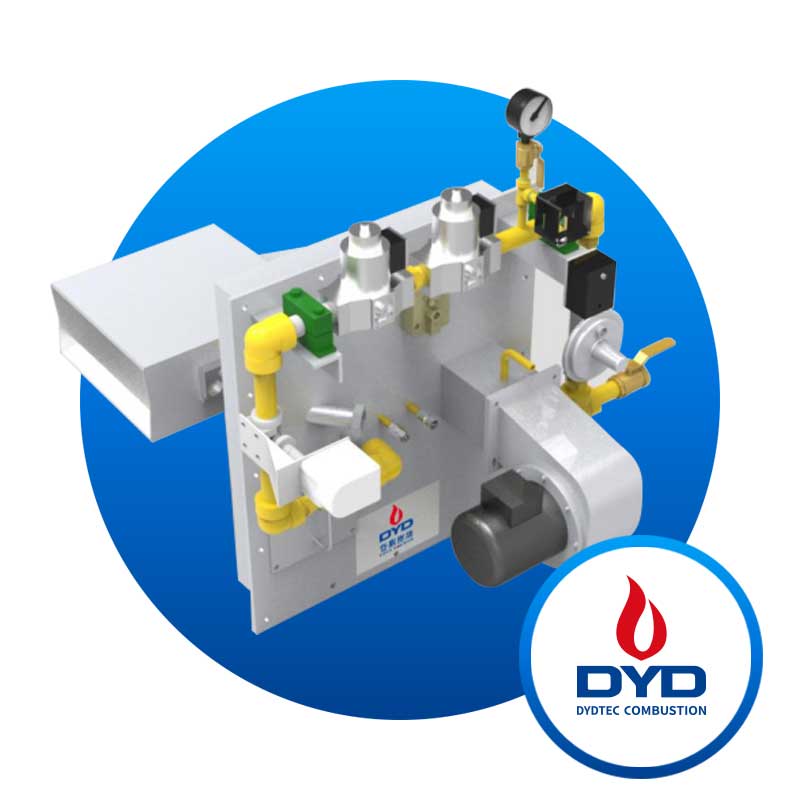

PLRSP Integrated System

Parameter

- Heating value: 293kw/ft

- Turndown ratio: 10:1

- Upstream temperature can reach 400℃

- Downstream temperature can reach 600 ℃

- Air velocity: 8-20 m/s

- Hearth back pressure range: -400Pa~+100Pa

- Gas inlet pressure: 20-30kpa

- Stable and clean combustion

- Low emission of nitrogen oxide

PTEC Integrated System

Parameter

- Heating value: 200-800Kw

- Turndown ratio: 10:1

- Combustion air: Normal temperature

- Hearth back pressure range: -2000Pa~+1000Pa

- System fuel: Natural gas, LPG

Parts

NT2010 Intelligent Modulating Actuator

The NT series intelligent modulating actuator is a high-performance actuator designed specifically for the combustion system. Equipped with a purge position control point, it can also be used as a conventional 4-20ma modulating actuator. The torque can be adjusted according to different rotational speed. Equipped with 4-20ma control and feedback, it can realize fully open and fully closed limit switch feedback. In addition, the fully open function of the blowing position has been customized, which can achieve the blowing function of the burner.

The surface of the actuator is equipped with a LCD display screen, a circular output shaft angle indicator, and a manually controlled hexagonal interface. The LCD screen can display valve settings and feedback in real-time, and can also be used to set some customized parameters.

Parameter

- 4-20MA actuator position control

- 4-20mA real time feedback of actuator position

- SW1 switch quantity forced action function: can be forced to fully open, forcibly close, and forcibly open to a custom position (LCD screen setting)

- With full open and full close limit feedback

- Adopting a 1.3-inch OLED large screen LCD with no visual angle limitation, high brightness, energy saving and environmental protection, real-time display of valve opening and feedback

- Switch to manual control mode and set the opening through the LCD screen

- In the power off state, the opening of the actuator can be manually adjusted using an inner hexagon spanner

- The actuator position can be set when there is no control signal: fully open, fully closed, held, custom position

- Customizable actuator switch speed, 10 to 30 seconds (slower speed, lower torque)

- Customizable control accuracy, with a maximum accuracy of 0.8%. The higher the accuracy, the more accurate it can be; the lower the accuracy, the lower the frequency of valve action, and the longer the service life

- High performance brushless motor with built-in overheating/overload protection

- Built in motor control module, capable of variable frequency speed control of the motor, achieving precise positioning and stepless speed regulation

- Real time prompt of fault menu (including faults caused by actuator jamming or other reasons causing actuator switch not in place)

- The system can restore factory settings through button operation

BFD1-U UV Flame Detector

BFD1-U series compact UV flame detector is suitable for gas, fuel oil and other single flame combustion applications. The UV sensor is designed to ensure that the flame detector will not misdetect the background radiation from thermal refractory or any other infrared light source.

Parameter

- Large photosensitive area and sensitive detection

- The product is fully sealed and filled with glue, with strong seismic resistance

- Equipped with an isolation lens with a pressure resistance of 15Kpa, which can effectively prevent water,heat, dust and corrosion in the furnace.

- With signal processing circuit, strong anti-interference

- Strong versatility, which can be used together with any program controller with ion bar access signal

- Can be connected to PLC or DCS digital input point

- High quality light tube, effectively preventing false detection

- Built-in ultraviolet sensor,amplifier and filter

- IP65 protection grade

- CE certification

Flame Relay

RF-FR-01 is a multifunctional flame relay that can be used with BFD1-U-I series flame detectors or flame rods. Its function is to converts from a flame detector open collector signal in a binary signal ON/OFF for access to systems such as PLC and DCS or indicator lights.

RF-FR-01 has two LEDs indicator of flame signal and power supply.

Compared to common products on the market, the unique feature is the integrated flame signal out response time selection function, which can be selected in 1 second or 3 seconds.

Parameter

- Power supply: 230VAC,50/60HZ

- Fused power rating: 100mA

- Suitable for flame detection: BFD1-U-I、flame rod

- Output signal: NO/NC、ON/OFF signal

- Contact rating: Max.250VAC,3A

- Installation: rail mounting

BCM-201-FS5 Series Combustion Controller

The Rapidflame BCM-201-FS5 combustion controller specially designed for direct-fire applications, which complies with the standard EN746-2. With its compact design and microprocessor-based control, aims to provide correct combustion sequence, flame ignition and detection for various process and industrial heating applications, either with fuel oil or fuel gas.

The indicators on BCM-201-FS5 panel provide abundant system status information, available to timely display 0-100% flame intensity、 current PLC stepping、 PLC status and failure information. with IP65 protection grade, BCM-201-FS5 could be installed on a side plate without the need of a wiring box.

BCM-201-FS5 provides two control modes – Panel control and Remote control, which can be switched through the button on panel.

Parameter

- For direct ignition or two-stage ignition

- Internal parameters can be modified

- Can be started locally or remotely

- After ignition, the ignition valve remains open or closed, which can be set through parameters

- By default, it is equipped with a communication interface, which can simultaneously control 100 controllers and read the required status information through communication

- Flame intensity and alarm information display

- IP64, can be installed independently without a control cabinet

- Purge waiting time can be set, and the purge function requires an external circuit (0-250s)

- Automatic ignition frequency can be set after ignition failure (0-4 times)

- The flame response time can be set (1-12 seconds)

- The ignition safety time can be modified, but it must comply with local standards

- Flame sensitivity can be set (1-9ua), with a default of 2ua

- The waiting time for rear blowing can be set (0-250s)

Explosion Proof Pressure Switch

The Rapidflame RFPS-EX series pressure switches are designed specifically for use in explosion-proof environments. The pressure switch adopts a diaphragm type and can be used for detecting gas pressure. The function of converting pressure signals into electrical signals can be achieved through the switch contacts. The pressure switch can be used alone or integrated into the gas control system.

Parameter

- Can be used for gas or air

- Can be used in gas explosion-proof environments Ex nR IIBT6 IP65

- The pressure can be adjusted (within the range)

- Multiple range options available

- Suitable for natural gas, LNG, LPG, air

Flow Regulating Valve(With actuator)

The NTRVP series gas flow control valve integrates Rapidflame NT2010 intelligent actuator, which is commonly used to integrate into gas valve groups and can accurately achieve gas/air ratio adjustment.

.jpg)

RTI Series Ignition Transformer

The RTI series ignition transformer is a device suitable for high-voltage ignition of gas burners. The ignition transformer can also be used on burners with single electrode operation. The ignition current and ionization current pass through a common electrode. The ignition transformer has a protection degree of IP00 and must be installed in the casing or in the control cabinet.