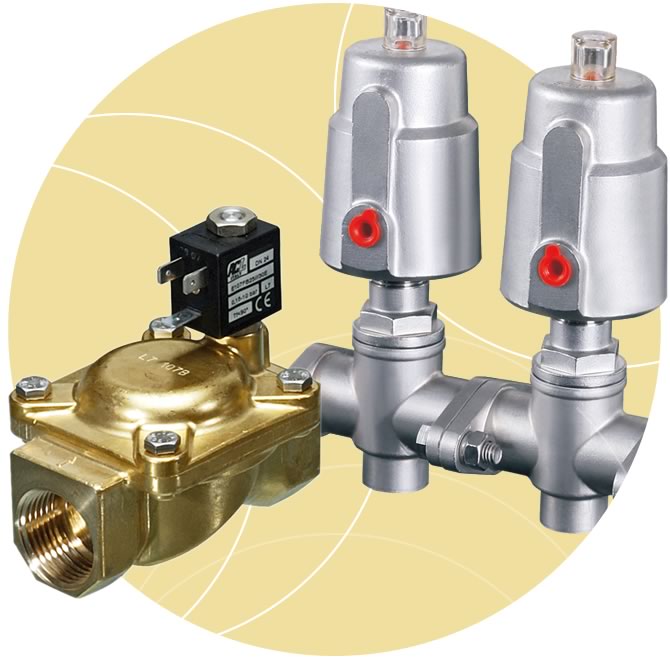

Products: ACL

ACL

Solenoid Valve Solutions

ACL S.r.l. is manufacturing a wide range of solenoid valves in different versions since 1987. Being focused on the satisfaction of customers’ needs, ACL is available to deal with all kind of requests concerning both standard and special products. ACL’s expertise is testified by the large number of customers worldwide, which are acting in all the industrial fields where the control of fluid is necessary.

View ACL Products

Series 106

DESCRIPTION

Solenoid valve 2 way normally closed direct acting poppet type

CONSTRUCTION

Body: Brass

Armature tube: AISI 303

Plunger and core: AISI 430FR

Springs: AISI 302

Seal material: NBR – FPM – EPDM – PTFE

FEATURES

Maximum allowable pressure PS 100bar

Maximum fluid viscosity 25cSt (mm2/s)

Ambient temperature: from -10°C to +80°C according to the coil

Universal mounting position

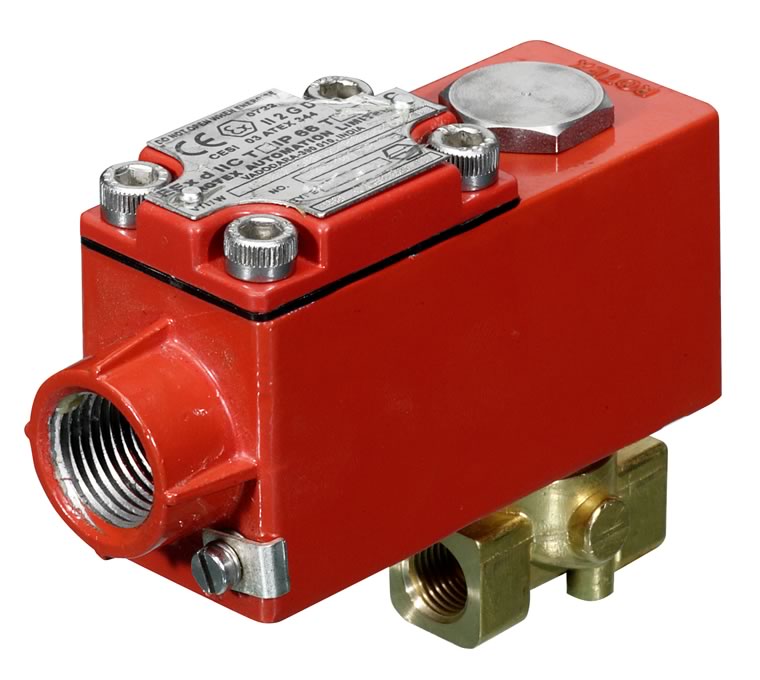

Series A106

DESCRIPTION

Solenoid valve 2 way normally closed direct acting poppet type. With explosion proof coil certified for hazardous area:

ATEX II 2GDEx d IIC T6 or T5 or T4 Gb

Ex tb IIIC T80°C or T95°C or T130°C Db IP66

Tamb -40°C ÷ +35°C(T6) or +50°C(T5) or +60°C(T4)

CESI 03 ATEX 344 Extension No. 01/12

(other certifications e.g.EAC, INMETRO, CCOE etc. on request)

VALVE CONSTRUCTION

Body: Brass

Seal material: NBR – FPM – EPDM

EXPLOSION PROOF COIL CONSTRUCTION

Housing: Red colour alloy (painted with epoxy powder)

Electrical connection: 1/2” NPT (M20x1.5 on request)

FEATURES

Maximum allowable pressure PS 100bar

Maximum fluid viscosity 25cSt (mm2/s)

Ambient temperature: -40°C ÷ +35°C(T6), +50°C(T5), +60°C(T4)

Mounting position with vertical coil above

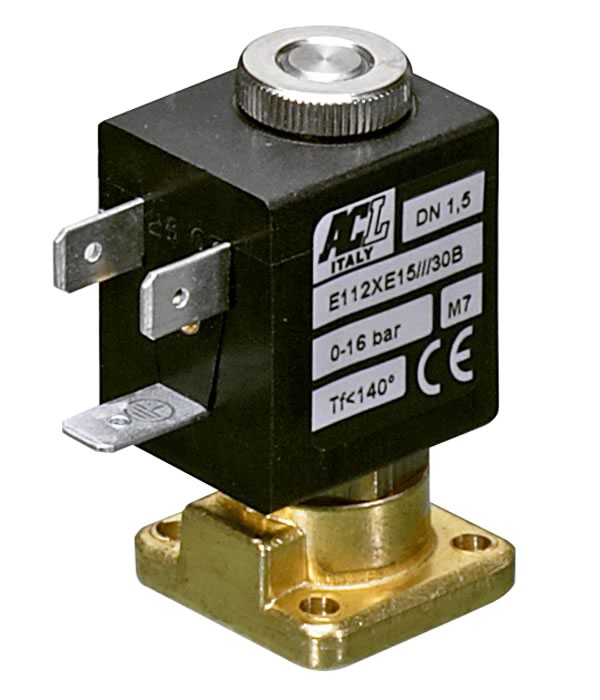

Series 112

DESCRIPTION

Solenoid valve 2 way normally closed

direct acting poppet type – Flange fixing

CONSTRUCTION

Body: Brass

Armature tube: Brass

Plunger and core: AISI 430FR

Springs: AISI 302

Seal material: NBR – FPM – EPDM

FEATURES

Maximum allowable pressure PS 50bar

Maximum fluid viscosity 25cSt (mm2/s)

Ambient temperature: from -10°C to +80°C according to the coil

Universal mounting position

Series 150

DESCRIPTION

Solenoid valve 2 way normally closed

direct acting with dry armature.

No metal parts in contact with the media.

CONSTRUCTION

Body: Acetal copolymer

Armature tube: Brass

Plunger and core: AISI 430FR

Springs: AISI 302

Seal material: SILICONE

FEATURES

Maximum allowable pressure PS 2bar

Maximum fluid viscosity 25cSt (mm2/s)

Ambient temperature: from -10°C to +80°C according to the coil

Preferred mounting position with vertical coil above

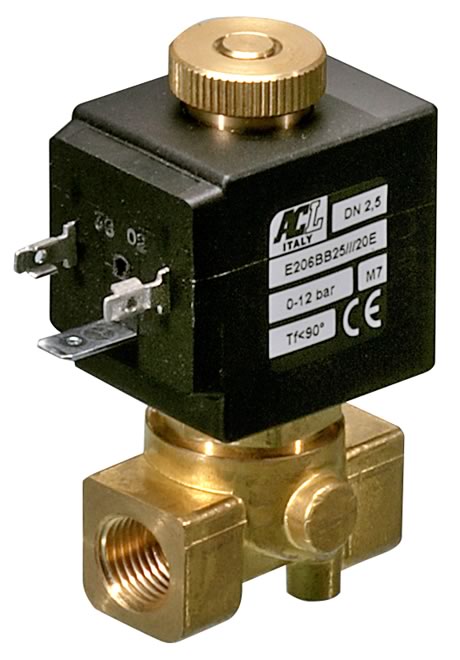

Series 206

DESCRIPTION

Solenoid valve 2 way normally open

direct acting poppet type

CONSTRUCTION

Body: Brass

Armature tube: Brass

Plunger and core: AISI 430FR

Springs: AISI 302

Seal material: NBR – FPM – EPDM

FEATURES

Maximum allowable pressure PS 50bar

Maximum fluid viscosity 25cSt (mm2/s)

Ambient temperature: from -10°C to +80°C according to the coil

Universal mounting position

Series 305

DESCRIPTION

Solenoid valve 3 way

direct acting poppet type

CONSTRUCTION

Body Brass

Armature: tube Brass

Plunger and core: AISI 430FR

Springs: AISI 302

Seal material: NBR – FPM – EPDM

FEATURES

Maximum allowable pressure PS 50bar

Maximum fluid viscosity 25cSt (mm2/s)

Ambient temperature: from -10°C to +80°C according to the coil

Universal mounting position

Series 320

DESCRIPTION

Solenoid valve 3 way direct acting poppet type.

The balanced seal and the special construction allows a big flow.

The solenoid valve can be used as normally closed,

normally open, mixing or diverting.

On request with position detector (with led).

CONSTRUCTION

Body: Anodized aluminium (series 320,321,322), AISI 303 (series 323,324,325)

Armature tube: AISI 303

Plunger and core: AISI 430FR

Springs: AISI 302

Seal material: FPM

FEATURES

Maximum allowable pressure PS 50bar

Maximum fluid viscosity 25cSt (mm2/s)

Ambient temperature: from -10°C to +80°C according to the coil

Universal mounting position

Series 350

DESCRIPTION

Solenoid valve 3 way normally closed

direct acting poppet type for modular construction

CONSTRUCTION

Body: Die-cast aluminium

Armature tube: Brass

Plunger and core: AISI 430FR

Springs: AISI 302

Seal material: NBR – FPM – EPDM

FEATURES

Media: Air, neutral gases

Ambient temperature: from -10°C to +80°C according to the coil

Universal mounting position

Series 107

DESCRIPTION

Solenoid valve 2 way normally closed with servo-assisted diaphragm

CONSTRUCTION

Body and cover: Brass

Armature tube: AISI 303

Plunger and core: AISI 430FR

Springs: AISI 302

Seal material: NBR – FPM – EPDM

FEATURES

Minimum differential pressure 0.15bar

Maximum allowable pressure PS 25bar

Maximum fluid viscosity 25cSt (mm2/s)

Ambient temperature: from -10°C to +80°C according to the coil

Preferred mounting position with vertical coil above

Series P150

DESCRIPTION

2 way normally closed angle seat valve pneumatically operated

PRESENTATION

High flow rate due to the angle seat configuration

Anti-water hammer feature with the fluid entry below the seat

Stainless steel and corrosion resistance body

Orientable pneumatic actuator

Self adjusting internal seal

Optical position indicator

Back pressure resistance capability

Maintenance free sealing pack

Universal mounting position

USE: Automation, heating, water, hot water, steam (180°C), aggressive and food fluid

CONNECTION: from 1/2” to 1” GAS or NPT

VALVE FEATURES

Fluid temperature: -40°C +180°C

Ambient temperature: -10°C +80°C

Fluid viscosity: max 600 cSt

Body material: Stainless steel AISI 316

Seal: PTFE

Packing gland: PTFE/FKM

PILOT ACTUATOR FEATURES

Fluid: Dry or lubrificated air, gases and neutral fluids

Fluid temperatures: max +60°C Body material

Stainless steel: AISI 316

Gaskets: NBR

Actuator: Ø50

Series P170

DESCRIPTION

2 way normally closed angle seat valve pneumatically operated

PRESENTATION

High flow rate due to the angle seat configuration

Anti-water hammer feature with the fluid entry below the seat

Stainless steel and corrosion resistance body

Orientable pneumatic actuator

Self adjusting internal seal

Optical position indicator

Back pressure resistance capability

Maintenance free sealing pack

Universal mounting position

USE: Automation, heating, water, hot water, steam (180°C), aggressive and food fluid

CONNECTION: from 1/2” to 2” GAS o NPT

VALVE FEATURES

Fluid temperature: -40°C +180°C

Ambient temperature: -10°C +80°C

Fluid viscosity: max 600 cSt

Body material: Stainless steel AISI 316

Seal: PTFE

Packing gland: PTFE/FKM

PILOT ACTUATOR FEATURES

Fluid: Dry or lubrificated air, gases and neutral fluids

Fluid temperatures: max +60°C

Body material: Polyamide 66 with 30% glass fibre

Gaskets: NBR

Actuator: Ø70

Series PM100

DESCRIPTION

2 way bi-stable (double acting) pneumatically operated valve.

Modular assembling.

PRESENTATION

Best choice for fluid mixing

Flanged connection modularity

Water hammer effect prevention

Protected visual position indicator

PTFE sealing pack

Maintenance free sealing pack

Pilot thread: G1/8”

Universal mounting position

USE: Packaging, Drinks Filling Machinery, Textile printing, Pharmacy & Medical Equipment, Chemical industry, Foaming Equipment, Water/sewage Disposal

CONNECTION: Threaded (BSP, NPT)

CONNECTION KIT:

Inlet plate (plate+OR+screws+nuts) Female – cod.14913000

Modules connection kit (OR+screws+nuts) – cod.14914000

End plate (plate+OR+screws+nuts) Male – cod.14915000

Threaded connection kit available on request

VALVE FEATURES

Fluid Pressure: Up to max 14bar

Control Pressure: from 4.5bar (see table)

Control Fluid: Neutral gas, Air

Body material: Stainless steel AISI 316

Sealing: PTFE

Actuator Material: AISI 304

Actuator: Size 50mm

Fluids: Water, Alcohol, Oils, Fuels, Steam, Natural gases or Liquids, Organic solvents, Acids and Lyes

Fluid viscosity: Max 600cSt (mm2 /s)

Fluid temperature: -10°C to +180°C

Ambient temperature: -10°C to +80°C

Control Type: Double acting (/NC and /NO)

Series PS100

DESCRIPTION

2 way normally closed angle seat valve pneumatically operated. Inlet under seat. Welded socket.

PRESENTATION

Welded Socket Valve Acc. to DIN 11850-2

Optional Socket Valve Acc. to DIN 11850-3

Water Hammer effect prevention (inlet under seat)

Protected visual position indicator

PTFE sealing pack

Maintenance free sealing pack

Double acting version available on request

Normally open version available on request

Pilot thread: G1/8” (G1/4” for 125 mm actuators)

Universal mounting position

USE: Packaging, Drinks Filling Machinery, Textile printing, Pharmacy & Medical Equipment, Chemical industry, Foaming Equipment, Water/sewage Disposal

CONNECTION: Welded Acc. to DIN 11850-2

VALVE FEATURES

Fluid Pressure: Up to max 16bar

Control Pressure: from 3.5bar (see tables)

Control Fluid: Neutral gas, Air

Body material: Stainless steel AISI 316

Sealing: PTFE

Actuator Material: AISI 304 or Aluminium (125 mm)

Actuator Size: 40mm, 50mm, 63mm, 90mm, 125mm

Fluids: Water, Alcohol, Oils, Fuels, Steam, Natural gases or Liquids, Organic solvents, Acids and Lyes

Fluid viscosity: Max 600cSt (mm2 /s)

Fluid temperature: -10°C to +180°C

Ambient temperature: -10°C to +80°C

Control Type: Normally closed (on request Normally open, Double acting)